Recycling technology

Recycling with innovative technologies

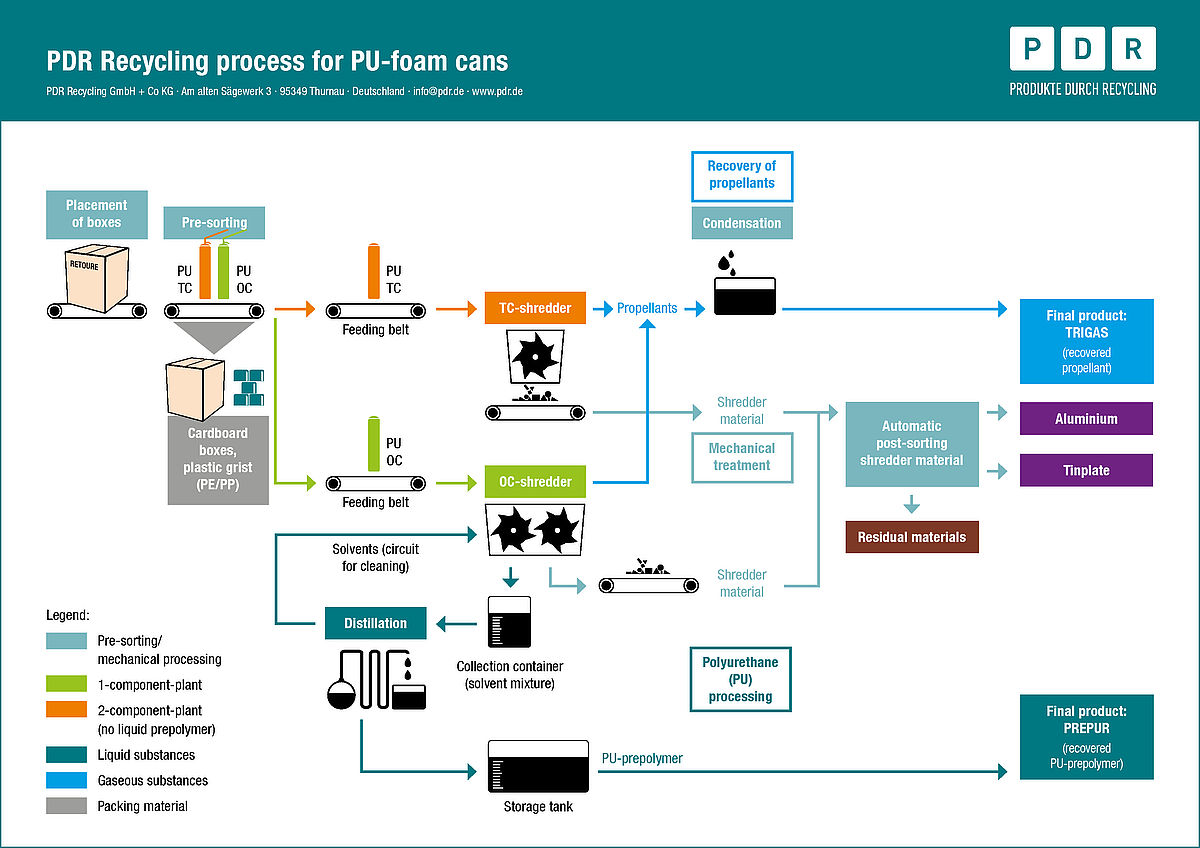

In order to achieve a high substantial utilisation quota, the latest process technology is necessary. In the worldwide unique plant for recycling of PU foam cans in Thurnau, the cans are mechanically shredded out of contact with air. The liquid contents and the metal can parts (aluminium and tin plate) drop into a solvent bath. A rinsing screw brings them out again and pre-washes them with the aid of rinsing jets.

Further washing and drying stages follow. A metal cutter sorts out the cleaned and dried aluminium and tin plate. The produced PUR solvent mixture is filtered several times and separated into PU and solvent. The propellants are extracted by suction and fluidised by pressure. The plastic caps of the cans are coarsely ground for the plastics compounding industry.

The following products and raw materials are generated:

The diagram gives an overview over the recycling process of used PU-foam cans at PDR.